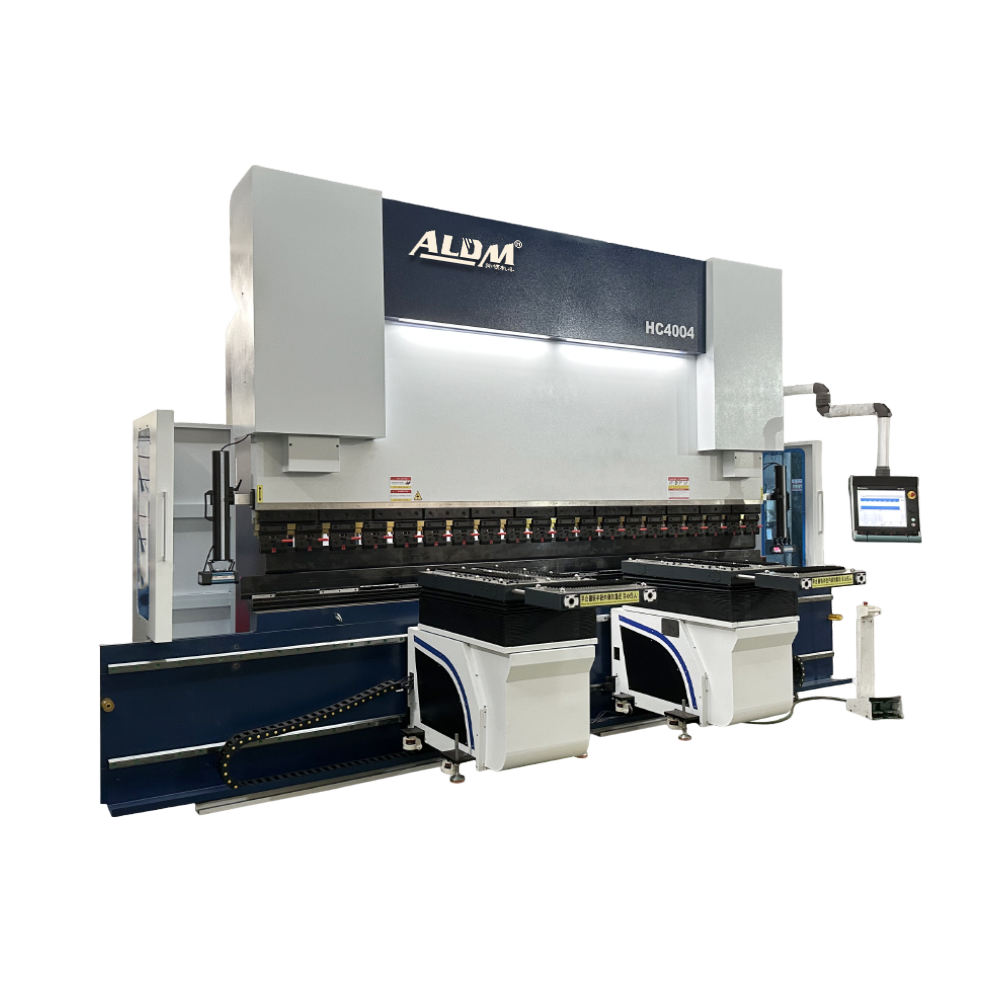

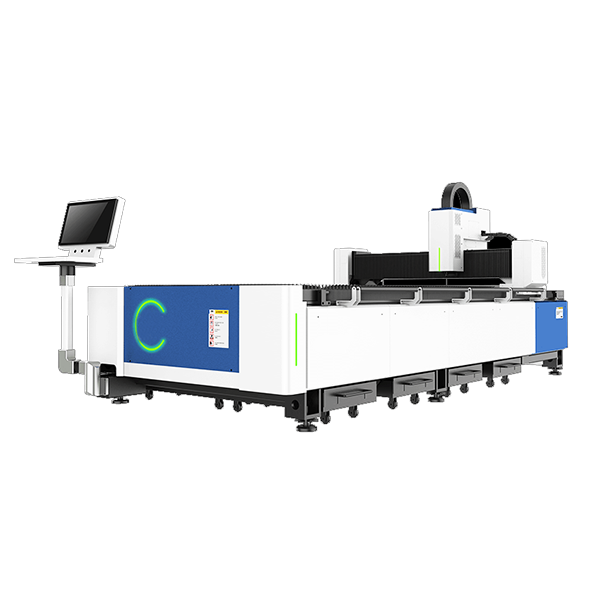

The press brake is a widely used machine in the metalworking industry, which is capable of performing precise bending operations on thin plates. In this article, we will analyse the principle of the press brake, its development history and its specific applications in various fields to help readers better understand this important tool.

The principle of press brake

The basic structure of the press brake includes the bracket, table and clamping plate. The table is placed on the stand and consists of a base and a clamping plate. The base is connected to the clamping plate by a hinge and consists of the seat shell, coil and cover. The coil is placed in a depression in the housing and the top of the depression is covered with a cover plate.

In use, the wire energises the coil, which generates an electromagnetic force that causes the platen to clamp the sheet between the bases. This electromagnetic clamping allows the platen to be adapted to a wide range of workpiece requirements and enables the processing of workpieces with sidewalls, making it easy and flexible to operate.

In addition, modern press brakes are equipped with a bending software programme tracking function. The encoder detects the bending feed distance and the robot can automatically run to the position matching the feed until the bending is complete. This feature enables employees who do not know how to programme to complete the commissioning in a short time.

History of press brakes

The development of press brakes can be traced back to the era of mechanical sheet metal working in the 18th century. The following are the main stages in the development of bending machines:

Middle of the 19th century: the first ‘sheet metal bending machine’ is born. Although the bending machine was very heavy at the time, it did make metal working easier.

The end of the 19th century: with the advent of the Industrial Revolution, mechanical sheet metal production began to take off. The invention of reversible rolling mills and other equipment further boosted the development of metalworking.

1930s: The first hydraulic bending machine is introduced. The introduction of hydraulic cylinders enabled bending operations to be automated, greatly improving productivity.

Early to mid-20th century: The electrification of bending systems increased and simple control systems were developed to control clamping, bending and cutting functions.

Around 1975: Manual bending machines were introduced, followed by press brakes with electric stops and electric scissors.

Applications of press brakes

Bending machine in the metal processing industry has a wide range of applications, especially in light industry, aviation, shipping, metallurgy, instrumentation, electrical appliances, stainless steel products, steel construction and decoration and other fields play an important role. The following are some specific application cases:

Automobile Manufacturing: In the process of automobile manufacturing, many parts need to be bent precisely, and the press brake plays a key role in this process.

Home Appliance Manufacturing: The shells, brackets and other components of home appliances often need to be bent, and press brakes provide an efficient and accurate solution for these operations.

Construction: Many components in steel buildings need to be bent, and press brakes ensure the accuracy and stability of these components.

Innovations and future trends

In recent years, press brake technology has continued to innovate with many new designs and features. For example, Nantong Starry Metal Technology Co., Ltd. has applied for a new patent titled ‘A Sheet Metal press brake for Easy Adjustment of Bending Angle’. Through the co-operative design of the adjusting mechanism and the driving mechanism, this press brake realises the precise adjustment of the clamping and bending angle of the sheet metal, which greatly improves the flexibility and efficiency of the operation.

With the transformation of manufacturing to intelligence and automation, press brakes are also introducing new technological elements. Although the current innovation has not yet directly involved AI technology, but its design concept and user experience enhancement is one of the steps towards intelligent development. In the future, the press brake is expected to have a more intelligent control system and data feedback and analysis functions, to help enterprises achieve more refined production management.

Conclusion

As an important equipment in the metal processing industry, the press brake has experienced the development process from manual operation to digital automatic control. Its principle is simple and efficient, widely used and important. With the continuous innovation of technology and the development of intelligent trend, the press brake will continue to play an important role in the manufacturing industry, providing efficient and accurate solutions for production in various fields.

Welcome to our main website!https://sc1094.searchtestsite.com/

Post time: 1 月-02-2025