Why Automotive Bending Demands Extreme Precision

In the race to produce lighter, safer vehicles, automakers increasingly adopt advanced materials like DP800 dual-phase steel and 6061-T6 aluminum. However, these materials pose significant challenges for bending processes:

Springback: Up to 15° angle deviation in high-strength steels.

Surface Scratching: 23% of aluminum parts fail cosmetic inspections (Source: Auto Manufacturing Quarterly).

Tight Tolerances: ±0.3° angle accuracy required for ADAS sensor brackets.

This case study reveals how Langdun collaborated with a leading auto parts manufacturer to overcome these hurdles, achieving:

✅ 98% First-pass Yield (from 65%)

✅ 15s Cycle Time per part

✅ $520k Annual Cost Saving

The Bending Nightmare in EV Chassis Production

Project Scope:

-

Part: EV battery tray support bracket (DP800 steel, 2.5mm thickness)

-

Specs: 12 bends with 0.5mm positional tolerance between holes

-

Pain Points:

-

35% rework rate due to springback-induced angle errors

-

8hr daily mold maintenance downtime

-

Diagnostic Data:

-

Thermal imaging showed inconsistent pressure distribution (Hotspots >220°C)

-

CMM measurements revealed 0.7° average angle deviation

4-Step Precision Bending Solution

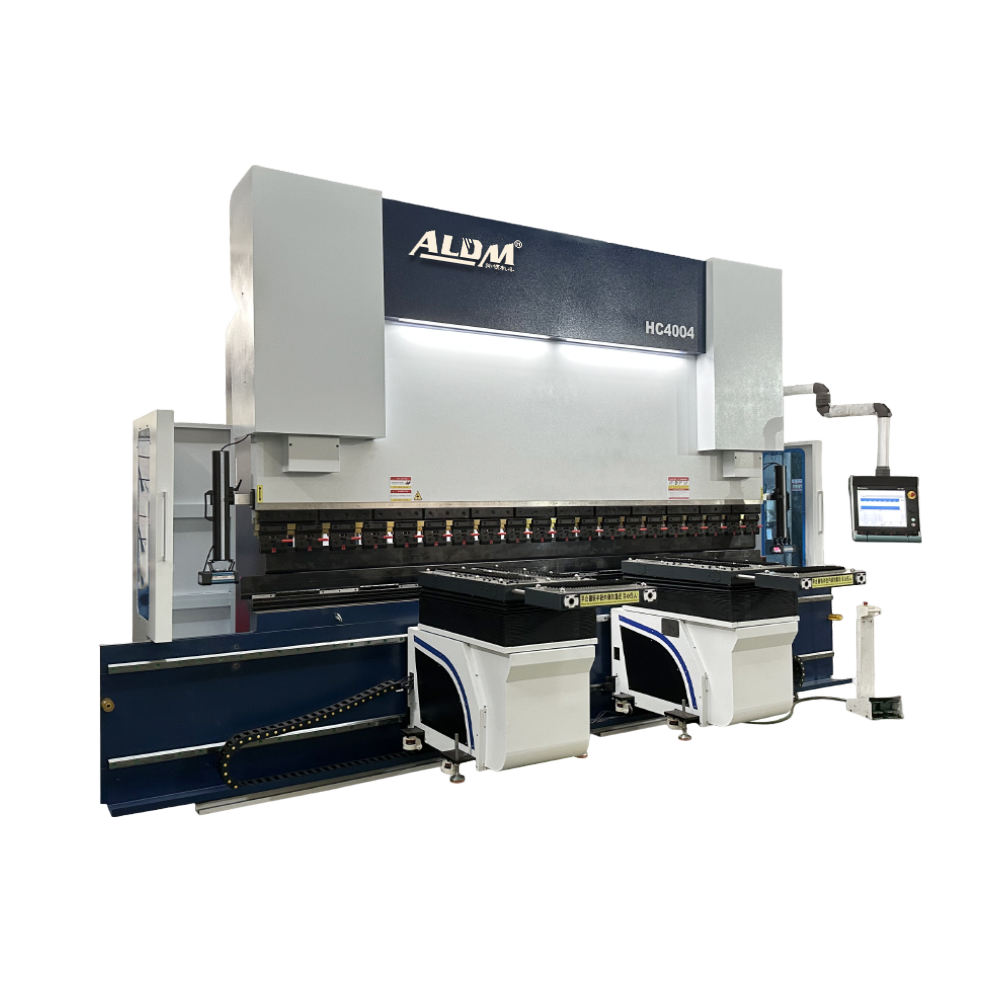

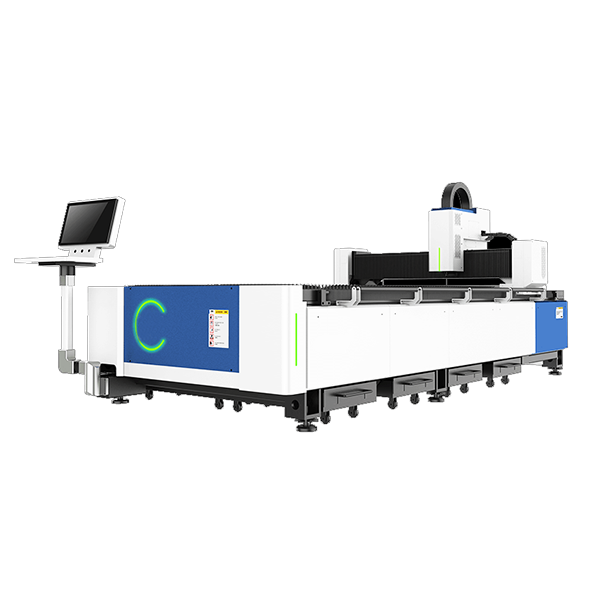

1. Material Prep & Machine Selection

-

Laser-Cut Edge Optimization:

Reduced edge roughness from Ra 12.5μm to Ra 3.2μm via fiber laser (prevents micro-cracks). -

Equipment:

Used with:-

0.0005° Backgauge Repeatability

-

400-ton Dynamic Crowning System

-

AI-Powered Springback Compensation

-

2. Smart Mold Design

-

Segmented Upper Die:

-

Carbide inserts at high-wear areas (extends life 3x)

-

Radius tolerance: ±0.01mm (prevents material galling)

-

-

Adaptive V-Die:

-

-

Width = 8 x Material Thickness (2.5mm → 20mm V-opening)

-

PTFE-coated for aluminum parts

-

3. Process Parameters Tuning

| Parameter | Before | Optimized |

|---|---|---|

| Bending Speed | 8mm/s | 15mm/s* |

| Dwell Time | 0.5s | 0.1s |

| Tonnage | 85t | 110t |

| *Fast approach → 5mm/s at contact |

4. Real-Time Quality Control

-

Laser Angle Sensors: 0.05° resolution, 100% in-process inspection

-

IoT Dashboard: Live monitoring of key metrics:

-

Ram parallelism (<0.02mm/m)

-

Tooling temperature (<50°C variance)

-

Cycle-to-cycle repeatability

-

Results: Data-Driven Success

Performance Comparison:

| Metric | Before | After | Improvement |

|---|---|---|---|

| Daily Output | 2,400 | 5,200 | 117% ↑ |

| Tooling Cost/Part | $0.38 | $0.12 | 68% ↓ |

| Energy Consumption | 18kWh | 11kWh | 39% ↓ |

| Customer Audit Score | 78 | 96 | 23% ↑ |

About Us

Nanjing langdun machine tool manufacture Co., Ltd, a famous and leading manufactory for sheet metal fabrications ma-chines, With 20 years industry-area experiences specially in shearing machine,press brake,rolling ,lathe,milling,laser and plasma cutting machines, the best timely and responsible service company in machinery area and reliable technical guidance,high technology self-design and structure update with innovation,-customer-oriented design,OEM and service dramatical achievement cooperation and collaboration.Company is located in mingjue industrial park, lishui district, nanjing, JiangSu province, 15km away from lukou international airport, nanjing, near No. 314 provincial road, with advantageous geographic location, easy and developed transportation.

Our company is complete in processing equipment, advanced in technology and process, owns a batch of experienced professional design personnel and ability for R& D and design of new products, in order to improve professional technical level and lay stress on technology content of products, this factory actively uses CAD, CAM, CAPP. Technology to improve new technology level of manufacturing products, this factory owns approximately 10 debugging technicians to ensure 100% qualification rate of exworks products. Currently products of this factory are not only best-selling in domestic market, but also exported to the Southeast Asia, South America and other countries and re-gions, and successfully enter into Euromarket. They are praised extensively by users.

Post time: 5 月-20-2025