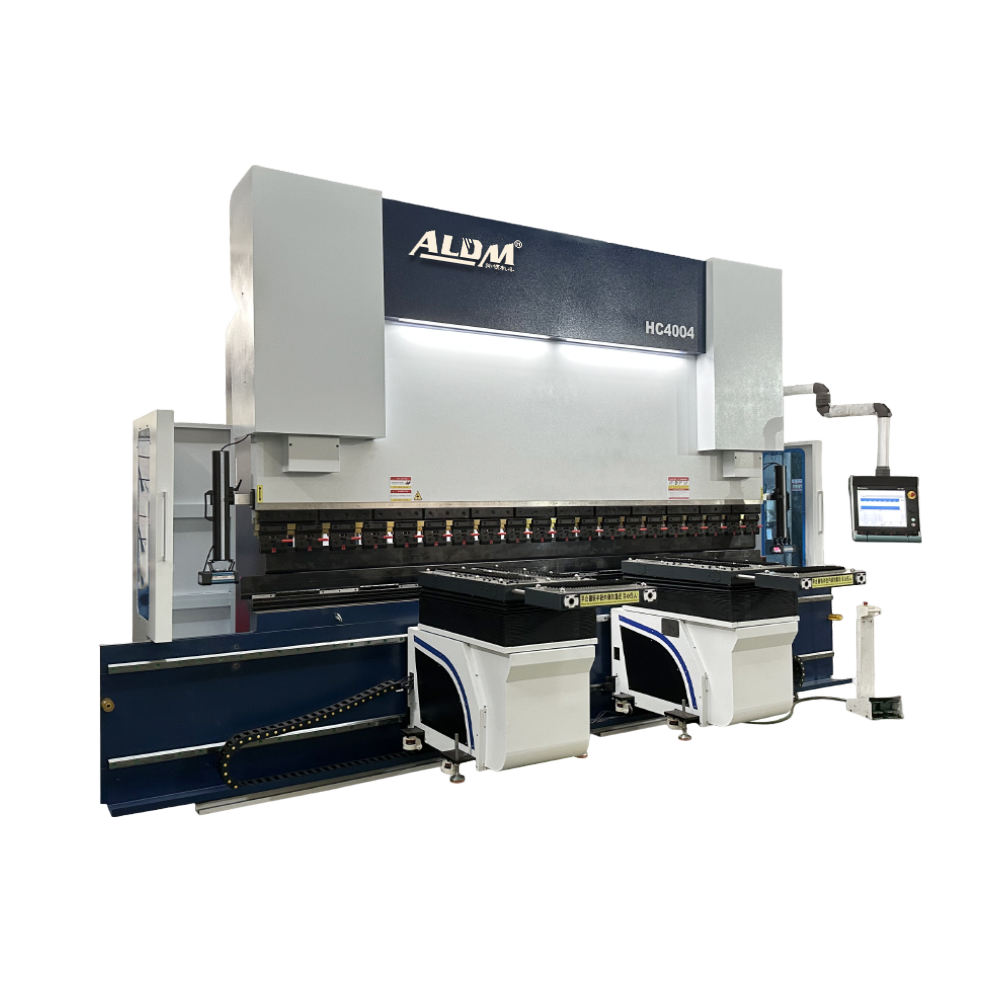

The press brake is one of the core pieces of equipment in sheet metal processing, widely used in mechanical manufacturing, the automotive industry, home appliance production, and other fields. For beginners, mastering press brake operation is not only the key to technical proficiency but also the inevitable path from novice to industry expert. This article will provide a systematic growth guide for beginners, covering foundational knowledge, operational standards, advanced techniques, and troubleshooting.

- Foundational Knowledge: Understanding Your “Steel Tailor”

Types and Structures of press brakes

Mechanical press brakes: Driven by an electric motor to store energy in a flywheel, suitable for bending medium to thick plates, offering high stability but slightly lower precision.

Hydraulic press brakes: Hydraulic systems provide adjustable pressure, making them suitable for high-precision and complex shape processing.

CNC press brakes: Equipped with CNC systems (e.g., DA52, Cybelec), they enable programmable control of bending angles and speeds, making them suitable for mass production.

Key Components: Upper die (blade), lower die (V-groove), rear stop, slide block, hydraulic system (or mechanical transmission).

Material and process parameters

Material types: Cold-rolled steel, stainless steel, aluminum sheets, etc. Different materials require adjustments to pressure and lower die V-groove width.

Bending coefficient: Material thickness (T), lower die V-groove width (V), and minimum bending radius (R) must satisfy the formula: V ≥ 6T (for general materials), R ≥ 0.5T (to prevent cracking).

- Operating Procedures: The Foundation of Safety and Efficiency

Safety Operating Guidelines

Protective Gear: Wear safety shoes, goggles, and gloves; long hair must be tied back.

Pre-startup Inspection: Confirm that the emergency stop button is functional, the slide block travel is unobstructed, and the hydraulic oil level is normal.

Operational Prohibitions: Do not insert hands into the die area; do not operate beyond the rated capacity (refer to the equipment nameplate tonnage).

Standardized Operating Procedures

Step 1: Programming/Parameter Settings

Manual Mode: Adjust the ram stroke and backstop position via the control panel.

CNC Mode: Import CAD drawings or manually input bending sequence, angle, and pressure values.

Step 2: Die Installation

Select upper and lower dies based on material thickness, ensuring the dies are securely fastened with no loosening.

Example: For bending 2mm steel plate, the recommended V-groove width is 12mm (6×2mm).

Step 3: Test Bending and Adjustment

After the first piece is tested, use an angle gauge to inspect; if the deviation exceeds 0.5°, adjust the pressure or compensation value accordingly.

Step 4: Mass Production

Regularly inspect the quality of bent parts, with angle and straightness checks every 20 pieces.

III. Advanced Techniques: From “Operating” to “Optimizing”

Bending Strategies for Complex Shapes

Multi-step Bending Sequence: Follow the principles of “short edges before long edges” and “small angles before large angles” to avoid interference.

Pre-Compensation for Reverse Deformation: When bending long parts, pre-bend in the opposite direction by 1-2° to offset springback.

Tips for Improving Efficiency

Quick Die Change: Use quick-change fixtures to reduce die change time from 30 minutes to 5 minutes.

Programming Optimization: Merge bending steps with the same angle to reduce ram idle travel.

Quality Defect Solutions

Angle Deviation: Adjust pressure or compensation values (CNC systems can set angle correction parameters).

Surface indentations: Increase the width of the lower die V-groove or use polyurethane sleeve dies.

Twisting deformation: Add a flattening process or use symmetrical bending methods.

- Advanced Techniques: Troubleshooting and Maintenance

Common fault handling

Ram cannot descend: Check hydraulic oil level, whether the solenoid valve is energized, and whether the safety light curtain is obstructed.

Unstable bending angle: Calibrate the pressure sensor and check the hydraulic system for leaks.

Inaccurate rear stop positioning: Re-calibrate the servo motor or replace worn ball screws.

Daily Maintenance Checklist

Daily: Clean mold oil residue and check hydraulic oil temperature (≤60°C).

Weekly: Lubricate guide rails and ball screws, and tighten electrical connections.

Monthly: Replace hydraulic oil filters and test system pressure.

- The Path to Mastery: Continuous Learning and Innovation

Knowledge Expansion

Study the “Metal Sheet Bending Process Manual” to understand the mechanical properties of different materials.

Attend industry exhibitions (such as the DMP Greater Bay Area Industrial Fair) to learn about the latest CNC systems and mold technologies.

Practical Innovation

Design specialized bending fixtures to address challenges in processing irregularly shaped parts.

Use simulation software (such as Radan Bend) to optimize bending sequences and reduce trial-and-error costs.

Conclusion

press brake operation is a “hands-on” skill. The transformation from novice to expert requires theoretical knowledge, practical experience, and continuous innovation. Remember: safety is the bottom line, precision is the lifeblood, and efficiency is the competitive edge. Master the techniques outlined in this article, and you will take a solid first step in the sheet metal processing field, with the potential to become an industry expert in process optimization and cost-effective efficiency improvements!

Feel free to click to watch and follow us on youtube!

https://www.youtube.com/@Langdun-machine

Post time: 6 月-20-2025